Domino Effect

Technical Paper: Oxistop Coatings for Boiler Tube Maintenance

Prepared for the: EPRI: Boiler Tube & HRSG Tube Failures & Inspections International Conference

October 16-18, 2007 • Calgary, Alberta, Canada

Download the PDF of this paper here

Introduction

OXISTOP, LLC, an Ohio based Limited Liability Company, is the sole distributor and applicator of the Oxistop line of ceramic coatings developed specifically for the fossil fuel power generation markets. In May of 2007, Oxistop International, LLC was formed to process the interest and demand for Oxistop Coatings in the international market.

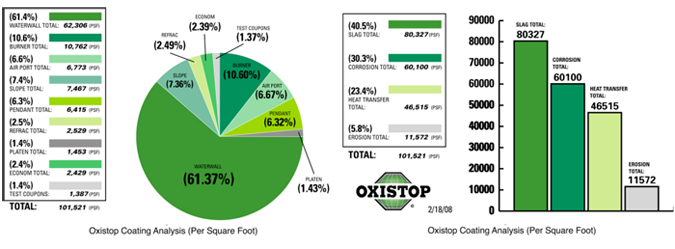

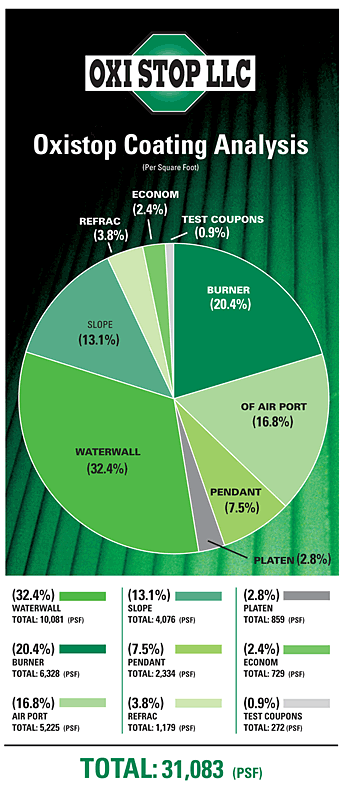

Power generated from fossil fuel combustion relies on boiler tube integrity. Boiler tube failure can be related to the destructive nature of slag, oxidation, corrosion, erosion and abrasion. These issues, Affecting boiler efficiencies and reliability are becoming increasingly important due to the worldwide demand for more power and operational controls related to emissions regulations.

At a fraction of the cost of current alternatives, the Oxistop line of coating materials has been proven to stop or minimize the damage caused by these destructive conditions. As an added benefit of utilizing these materials, boiler tubes coated with Oxistop coatings will maintain optimum heat transfer into boiler water wall tubes by replacing the iron oxide protective (and insulating) layer and residue build-up that occurs when boiler tubes are subjected to high heat and coal combustion with a ceramic based protective barrier. This protective barrier will resist slag buildup that will decrease heat transfer through the boiler tube.

History and Use

Oxistop, LLC was formed in the spring of 2004 (Oxistop International, LLC, formed in 2007) in by a number of partners with extensive power generation maintenance problem solving experience. The company is the exclusive distributor and installer of Oxistop coatings and to date, almost 100,000 square feet of the coating has been installed nationally and worldwide.

As a result of successful early trial applications and high interest in the industry in cost effective solutions to maintenance issues pertaining to boiler reliability, many repeat orders have resulted from over ninety-five (95) initial applications in thirty-three (33) different states and countries.

Continue Reading | Comments Off on Domino Effect

PRB Coal Users’ Group

Click here for the PDF version of this paper

Introduction

OXISTOP, LLC, an Ohio based Limited Liability Company, is the sole distributor and applicator of the Oxistop line of ceramic coatings developed specifically for the fossil fuel power generation markets. In May of 2007, Oxistop International, LLC was formed to process the interest and demand for Oxistop Coatings in the international market.

Power generated from fossil fuel combustion relies on boiler tube integrity. Boiler tube failure can be related to the destructive nature of slag, oxidation, corrosion, erosion and abrasion. These issues, Affecting boiler efficiencies and reliability are becoming increasingly important due to the worldwide demand for more power and operational controls related to emissions regulations.

Continue Reading | Comments Off on PRB Coal Users’ Group

High Emissivity

Use of ceramic coatings to enhance

performance of metal furnace components

Effect of High Emissivity

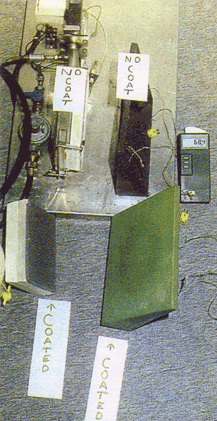

In addition to the dramatic increase in service life experienced, the high emissivity ceramic coatings advantageously influence the rate of thermal processing and thus the amount of energy expanded during the process. This fact has been shown by test results from a demonstration furnace arrangement as shown in Fig. 1. Evaluated with this furnace set up were the high emissivity ceramic coatings (MC19-GRP for metals and REF30-GY for refractories) on the heat absorption of the coated metal target.

In addition to the dramatic increase in service life experienced, the high emissivity ceramic coatings advantageously influence the rate of thermal processing and thus the amount of energy expanded during the process. This fact has been shown by test results from a demonstration furnace arrangement as shown in Fig. 1. Evaluated with this furnace set up were the high emissivity ceramic coatings (MC19-GRP for metals and REF30-GY for refractories) on the heat absorption of the coated metal target.

The three principal, influencing components involved in this test are burner block, the carbon steel plate target, and the propane gas fuel. In this gas-fired, radiant type of heating unit, test were conducted with the high alumina burner block (4″Lx5″Hx1″W) coated (REF30-GY) and uncoated and with the carbon steel plate coated (MC19-GRP) and uncoated.

In the test the furnace was fired until a temperature of 250°F was recoreded by the thermocouple on the back side of the uncoated carbon steel target and then it was allowed to cool to 200°F before the time-temperature readings were taken upon heat up to 800°F. The complete test results are shown in Table III and Fig. 2.

The first test (1) was run as a base line with both the carbon steel target and burner block uncoated. The time required to reach a temperature of 800°F was 114 seconds.

The second test (2) was conducted with the carbon steel target coated with the high emissivity ceramic coating for metals, MC19-GRP, and the burner block uncoated. The time required to reach a temperature of 800°F from the starting temperature of 200°F was 101 seconds or an 11% time reduction from the base-line results.

The third test (3) was performed with the carbon steel target uncoated and the burner block coated with the high emissivity ceramic coating for refractories, REF30-GY. The time required to reach a temperature of 800°F from the starting temperature of 200°F was 86 seconds or a 25% time reduction from the base-line results.

The fourth test (4) was run with the carbon steel target coated with the high emissivity ceramic coatings for metals, MC19-GRP, and the burner block coated with the high emissivity ceramic coating for refractories, REF30-GY. The time required to reach a temperature of 800°F from the starting temperature of 200°F was 83 seconds or a 27% time reduction from the base-line reading.

As demonstrated, the heat absorption of metal can be greatly increased by the addition of a high emissivity ceramic coating. Higher heat absorption rate can provide these benefits: (1) improved efficiency of radiant tube fired furnaces; (2) quicker and more uniform heat-ups and reduce operating time in returning the furnace to the required operating temperature; (3) improved efficiencies of both metallic and refractory heating elements; (4) improved service life due to the reduction of temperature gradients in the coated metal component; (5) increased production, improved quality and reduced maintenance.

Continue Reading | Comments Off on High Emissivity

OXISTOP Coatings—For Boiler Tube Maintenance

Click here to see PDF file of the paper

INTERNATIONAL CONFERENCE

On Advances in Condition and Remaining Life Assessment for Fossil Power Plants

October 16 – 18, 2006 Louisville, Kentucky

Technical Paper: Oxistop Coatings For Boiler Tube Maintenance

The authors

Tim E. Batton, President and Senior Managing Partner

Al Bracey, Director of Materials and Installation

Introduction

Introduction

OXISTOP, LLC, an Ohio based Limited Liability Company, is the sole distributor and applicator of the Oxistop line of ceramic coatings developed specifically for the fossil fuel power generation and traditional refractory markets. Both markets currently experience failure and high maintenance costs related to maintaining key components of production.

Power generated from fossil fuel combustion relies on boiler tube integrity. Boiler tube failure can be related to the destructive nature of slag, oxidation, corrosion, erosion and abrasion. These issues are becoming increasingly important due to the worldwide demand for more power and operational controls related to emissions regulations.

At a fraction of the cost of current alternatives, the Oxistop line of coating materials has been proven to stop or minimize the damage caused by these destructive conditions. As an added benefit of utilizing these materials, boiler tubes coated with Oxistop coatings will maintain optimum heat transfer into boiler water wall tubes by replacing the iron oxide protective (and insulating) layer and residue build-up that occurs when boiler tubes are subjected to high heat and coal combustion with a ceramic based protective barrier. This protective barrier will resist slag buildup that will also decrease heat transfer through the boiler tube.

Continue Reading | Comments Off on OXISTOP Coatings—For Boiler Tube Maintenance