High Emissivity

Use of ceramic coatings to enhance

performance of metal furnace components

Effect of High Emissivity

In addition to the dramatic increase in service life experienced, the high emissivity ceramic coatings advantageously influence the rate of thermal processing and thus the amount of energy expanded during the process. This fact has been shown by test results from a demonstration furnace arrangement as shown in Fig. 1. Evaluated with this furnace set up were the high emissivity ceramic coatings (MC19-GRP for metals and REF30-GY for refractories) on the heat absorption of the coated metal target.

In addition to the dramatic increase in service life experienced, the high emissivity ceramic coatings advantageously influence the rate of thermal processing and thus the amount of energy expanded during the process. This fact has been shown by test results from a demonstration furnace arrangement as shown in Fig. 1. Evaluated with this furnace set up were the high emissivity ceramic coatings (MC19-GRP for metals and REF30-GY for refractories) on the heat absorption of the coated metal target.

The three principal, influencing components involved in this test are burner block, the carbon steel plate target, and the propane gas fuel. In this gas-fired, radiant type of heating unit, test were conducted with the high alumina burner block (4″Lx5″Hx1″W) coated (REF30-GY) and uncoated and with the carbon steel plate coated (MC19-GRP) and uncoated.

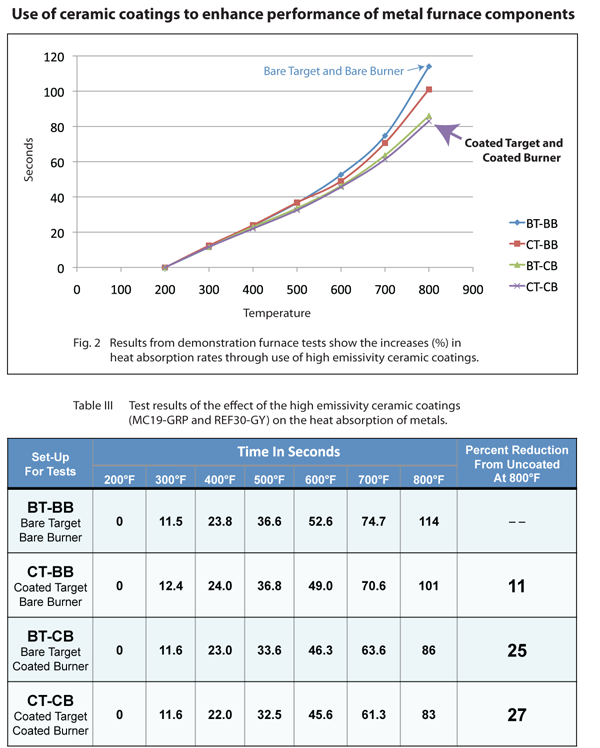

In the test the furnace was fired until a temperature of 250°F was recoreded by the thermocouple on the back side of the uncoated carbon steel target and then it was allowed to cool to 200°F before the time-temperature readings were taken upon heat up to 800°F. The complete test results are shown in Table III and Fig. 2.

The first test (1) was run as a base line with both the carbon steel target and burner block uncoated. The time required to reach a temperature of 800°F was 114 seconds.

The second test (2) was conducted with the carbon steel target coated with the high emissivity ceramic coating for metals, MC19-GRP, and the burner block uncoated. The time required to reach a temperature of 800°F from the starting temperature of 200°F was 101 seconds or an 11% time reduction from the base-line results.

The third test (3) was performed with the carbon steel target uncoated and the burner block coated with the high emissivity ceramic coating for refractories, REF30-GY. The time required to reach a temperature of 800°F from the starting temperature of 200°F was 86 seconds or a 25% time reduction from the base-line results.

The fourth test (4) was run with the carbon steel target coated with the high emissivity ceramic coatings for metals, MC19-GRP, and the burner block coated with the high emissivity ceramic coating for refractories, REF30-GY. The time required to reach a temperature of 800°F from the starting temperature of 200°F was 83 seconds or a 27% time reduction from the base-line reading.

As demonstrated, the heat absorption of metal can be greatly increased by the addition of a high emissivity ceramic coating. Higher heat absorption rate can provide these benefits: (1) improved efficiency of radiant tube fired furnaces; (2) quicker and more uniform heat-ups and reduce operating time in returning the furnace to the required operating temperature; (3) improved efficiencies of both metallic and refractory heating elements; (4) improved service life due to the reduction of temperature gradients in the coated metal component; (5) increased production, improved quality and reduced maintenance.